bonyadi magazine

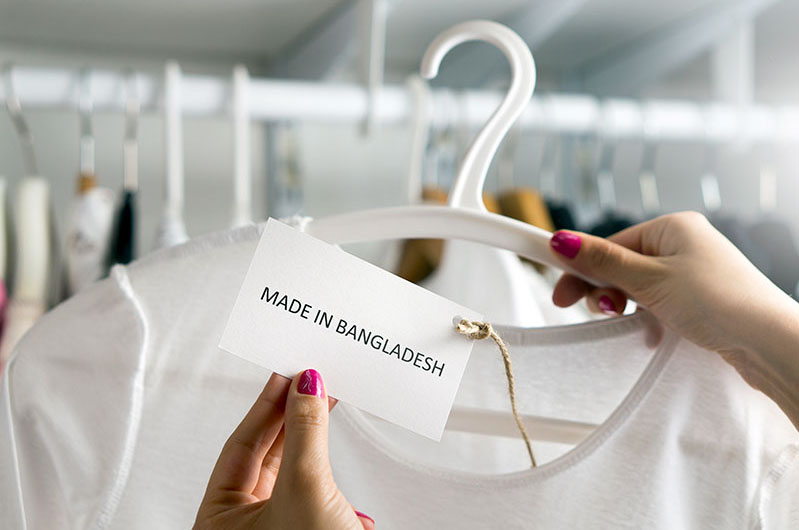

Immago and the Bangladesh apparel industry

Although smaller in size than its neighbours, the Bangladesh apparel industry is one of the largest in the world. Immago are proud to have a base in this hard-working and industrious country

Bangladesh industry today

For a country that gained independence only 50 years ago, Bangladesh has done remarkably well in the apparel industry

In fact, it is second only to China when it comes to garment exports, with the ready-made garment (RMG) industry accounting for 84% of Bangladesh’s exports

The garment industry in Bangladesh began in the 1980s, practically started by only one man, Nurool Quader Khan

Khan had a vision of how to transform the country, and in 1978, he sent 130 trainees to South Korea where they learned how to produce readymade garments. When those trainees returned, he set up Desh Garments, which was closely followed by other entrepreneurs who also set up apparel factories

In that year, 1978, garment exports totalled $10,000. In the 2018-19 financial year, they totalled over 34 Billion USD

Today the country has around 3,500 textile factories, exporting to 167

countries around the world

The disasters that led to change

The Bangladesh garment boom over the past decade can be traced to two horrific incidents in 2012 and 2013 that forever changed the country’s industry

On 24 November 2012, a factory fire broke out in the Tazreen Fashion factory in the Ashulia district on the outskirts of Dhaka. At least 117 people were confirmed dead in the fire, and over 200 were injured, making it the deadliest factory fire in the nation’s history

The following April an eight-story commercial building called Rana Plaza collapsed. The search for the dead ended three weeks later with a death toll of 1,134 – this was the deadliest garment-factory disaster in history and the deadliest industrial accident in the history of Bangladesh

These two disasters highlighted massive problems in working conditions in the country, prompting some international buyers to stop sourcing from Bangladesh, resulting in the United States withdrawing its preferential tariff agreement

This led to a complete overhaul of the industry’s health and safety laws, along with the RMG sector becoming a frontrunner in transparency and responsibility

These measures forced the closure of hundreds of unsafe, bottom-tier factories, helping restore Bangladesh’s attractiveness in the global apparel-sourcing market and leading to a decade of rapid growth

The pandemic

Unfortunately, that growth was brought to a crashing halt by the pandemic

Global lockdowns triggered order reductions, cancellations, payment delays, and renegotiation of terms. Many smaller, less well-funded factories closed their doors for good as Covid-19 threatened the lives and livelihoods of Bangladeshi workers

As the second largest exporter of apparel, when the world came to a stop, the country was hit hard. The value of Bangladesh’s RMG exports fell by 17% in the first year of the pandemic, representing revenue losses of up to $6 billion

Sustainability

The good news is Bangladesh is bouncing back, and they’re also leading the way in sustainability

The country is now home to the most Leadership in Energy and Environmental Design (LEED) green factories in the world.

These new factories use solar panels, reduce water consumption, and recycle waste. The aim is to switch to a circular economy, reducing the industry’s carbon footprint